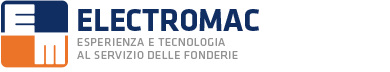

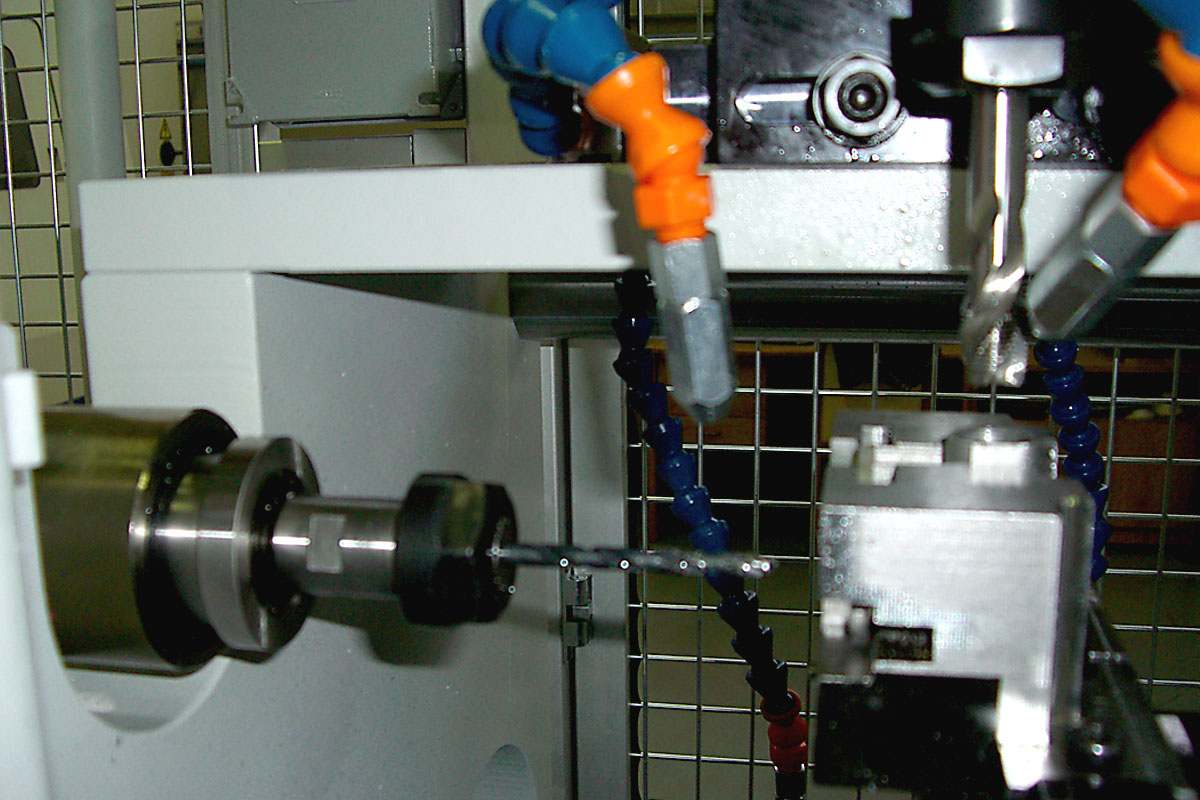

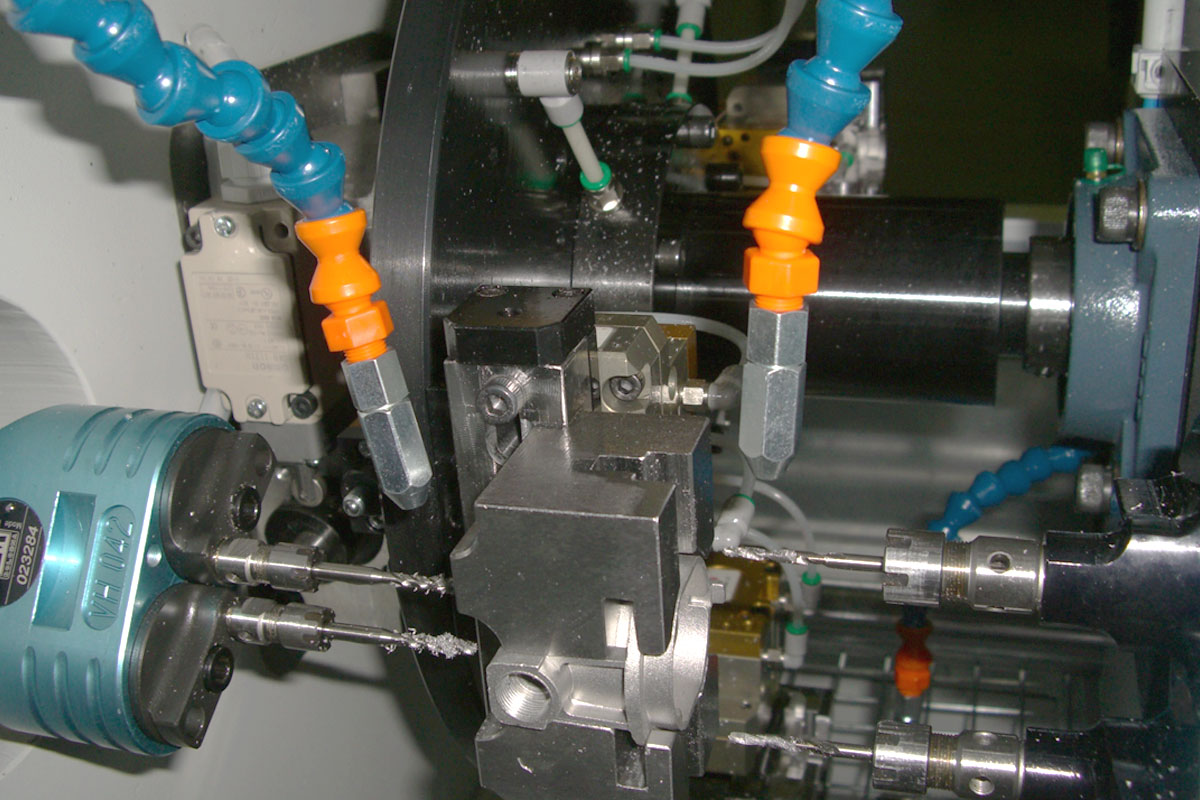

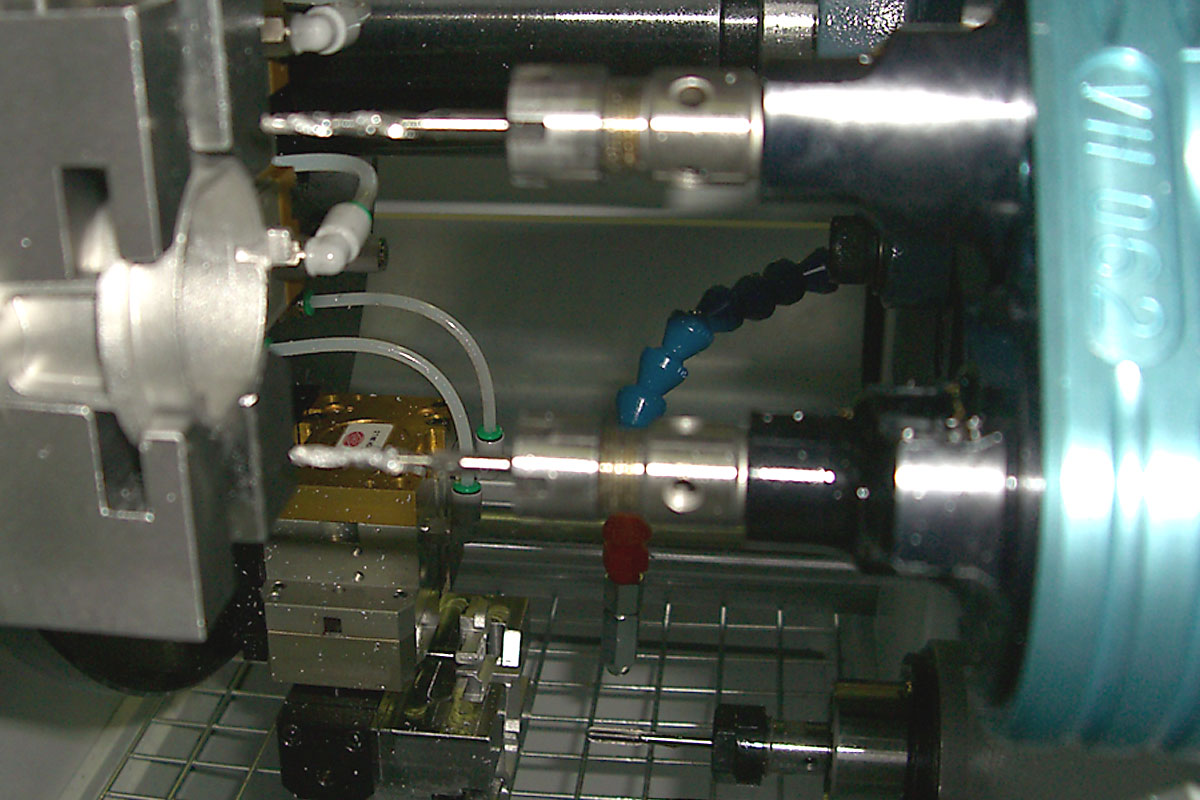

Machine with 5 work units for aluminium threading

DESCRIPTION OF THE TRANSF-GeH5 MACHINE

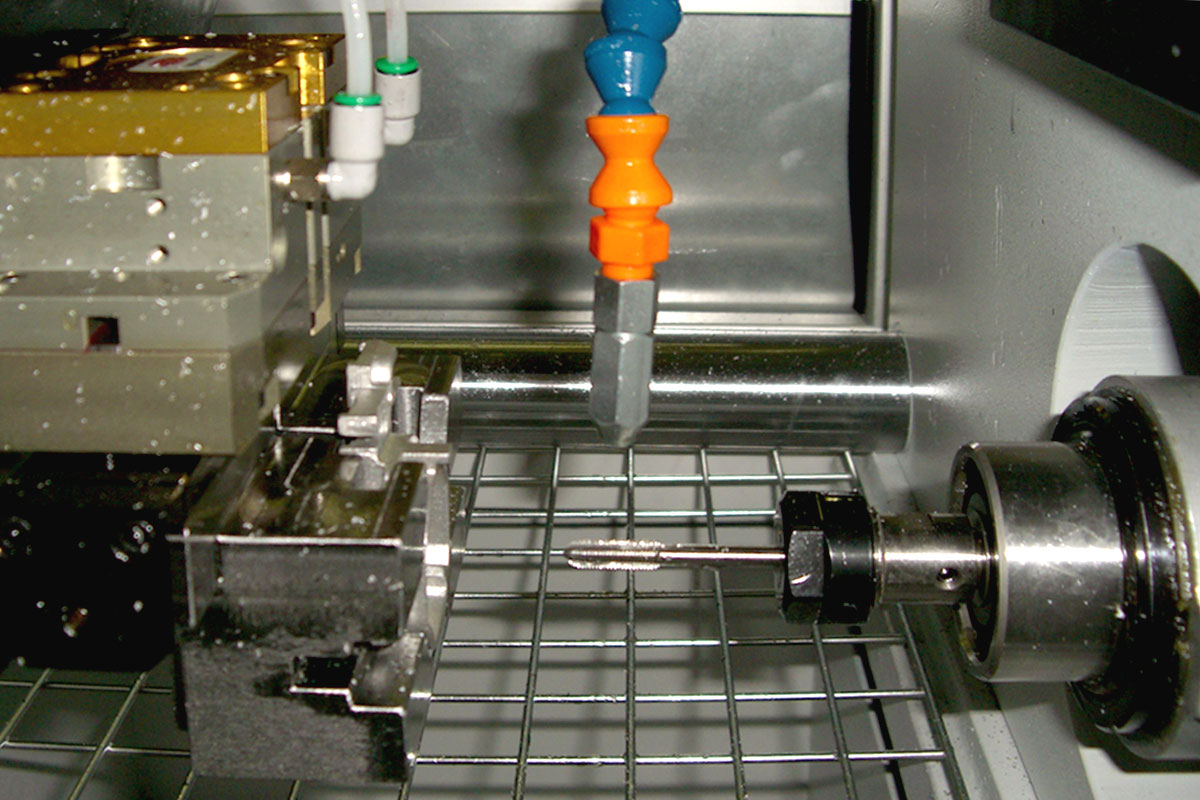

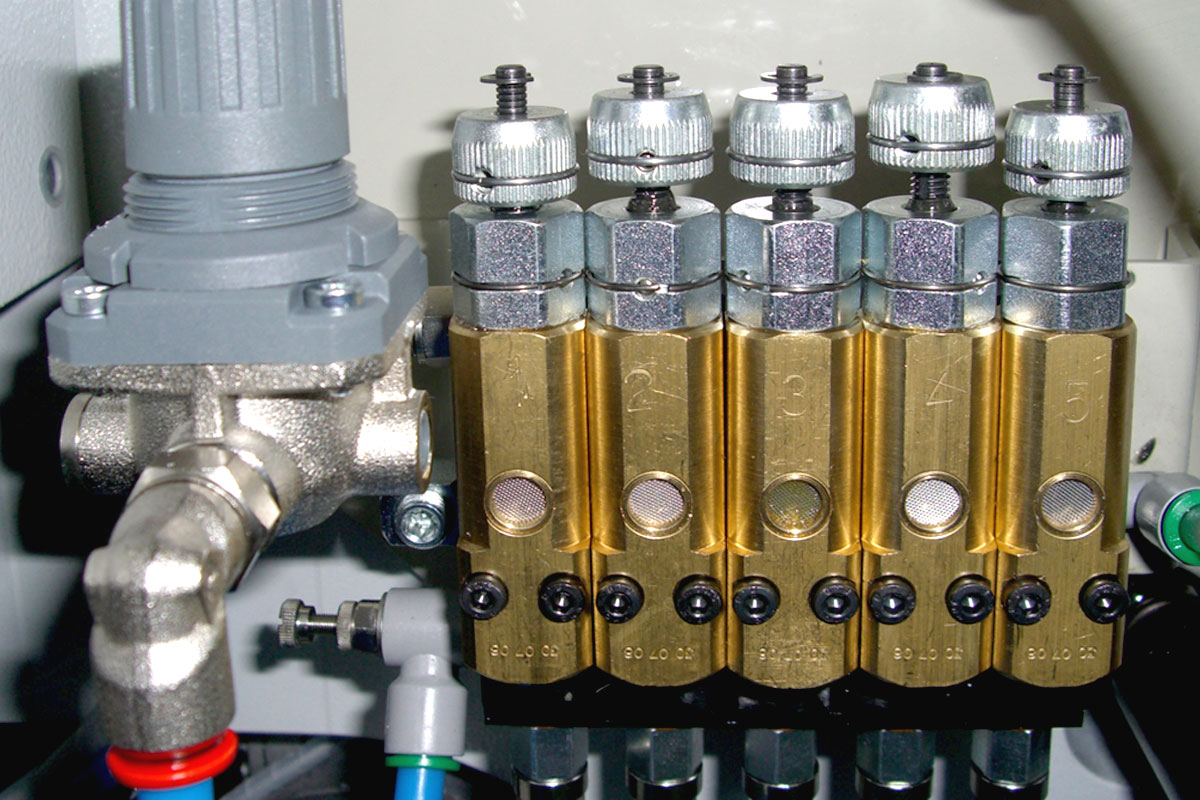

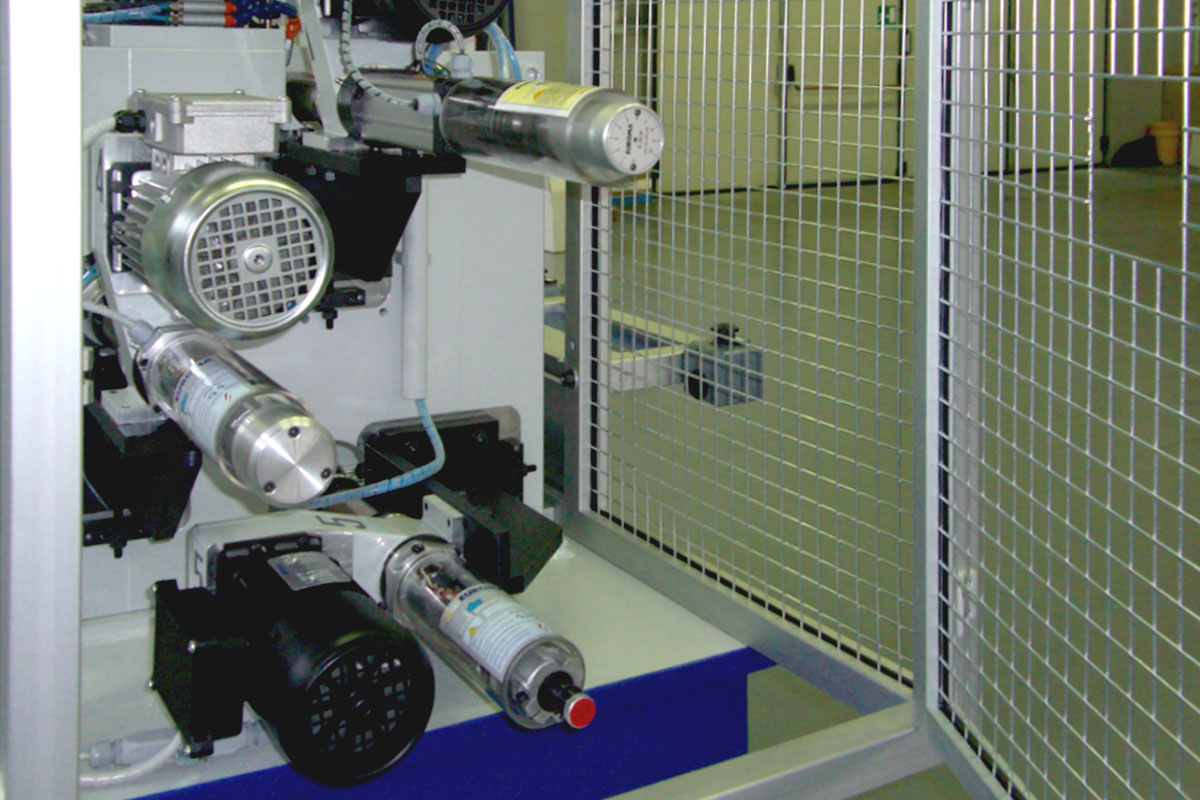

Electro Mac Srl offers its customers a highly innovative range of machines for foundries and for high and very great precision processing in general. The Company has developed a series of top quality industrial systems also in the field of aluminium threading, like, for example, the TRANSF-gEh5 threading machine equipped with 5 work units and with all possible accessories to make processing safe, simple and fast. The base of the structure is made of electro-welded, normalized steel. A rotating vertical table mod. RIG 06-04-270 VLRA-VCT sits on this structure, equipped with a 0.37 kW 4-position motor with a 400 mm steel disc and a compressed air dispenser for blocking parts. The system is also equipped with a pneumatic closure system to fix the position of the table. Further 4 pneumatic clamps mod. RDH-3M with parallel opening block the parts being processed. The threading machine manufactured by Electro Mac Srl is equipped with an automatic lubrication system with a pump ad a tank with a capacity of up to 5 litres. A control panel with a backlit display, pushbuttons and control warning lights is located on the machine. A complete kit of terminals guarantees the gas valve tightness and the aluminium perimeter guard makes the system reliable and safe. The first work unit of the TRANSF-GeH5 threading machine makes it possible to drill 5.5 diameter holes using the EUROMA F.P13.75.1730 MODEL. Electromechanical tapping takes place at 0.75 kW and the stroke is 75 mm. The second unit threads M4 holes with the EUROMA system mod. M13.50.1400. The 0.75 kW drilling is electro-mechanical and the unit is equipped with a head with two spindles mod. V2.042.P with a distance between the axles which can be adjusted from 13.5 to 69.5 mm. Unit no. 3 carries out the tapping of M6x0.50 holes using the EUROMA system, mod. M13.100.1050. The 0.55 kW tapping is electro-mechanical and the fast stroke is 50 mm. The fourth unit makes it possible to process 12.6 diameter holes and 45° conuses using the EUROMA system mod. F.31.2900.2CO. Electro-mechanical tapping is carried out at 0.55 kW, the stroke is 50 mm and the system is equipped with a pneumatic transfer unit mod. S.USPK.100. The fifth work unit makes it possible to thread M13X1.5 holes with the EUROMA system mod. M.21.80.A and to carry out 0.55 kW tapping./span>

APPLICATIONS

- Ø5.5 drilling

- M4 threading

- M6X0,50 tapping

- Ø12.6 processing + 45° conus

- M13X1.5 threading

ADVANTAGES

- Reduction of machine downtimes

- Increased cutting speed

- Longer duration of the drill bit

- Higher productivity

- Simpler to use

- Better economic advantages

- Average hourly production: 700/800 elements