Machine with 8 work units for aluminium threading

DESCRIPTION OF THE EM05/T7P5 MACHINE

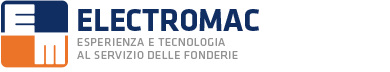

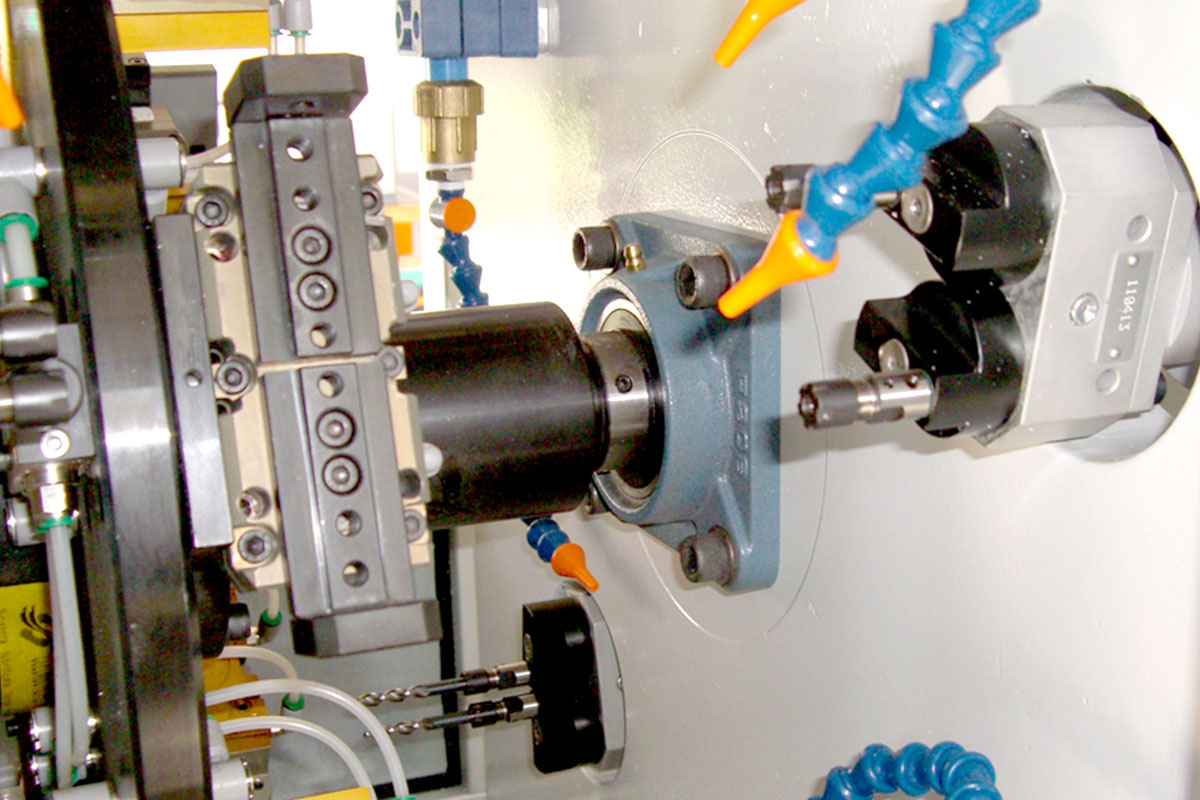

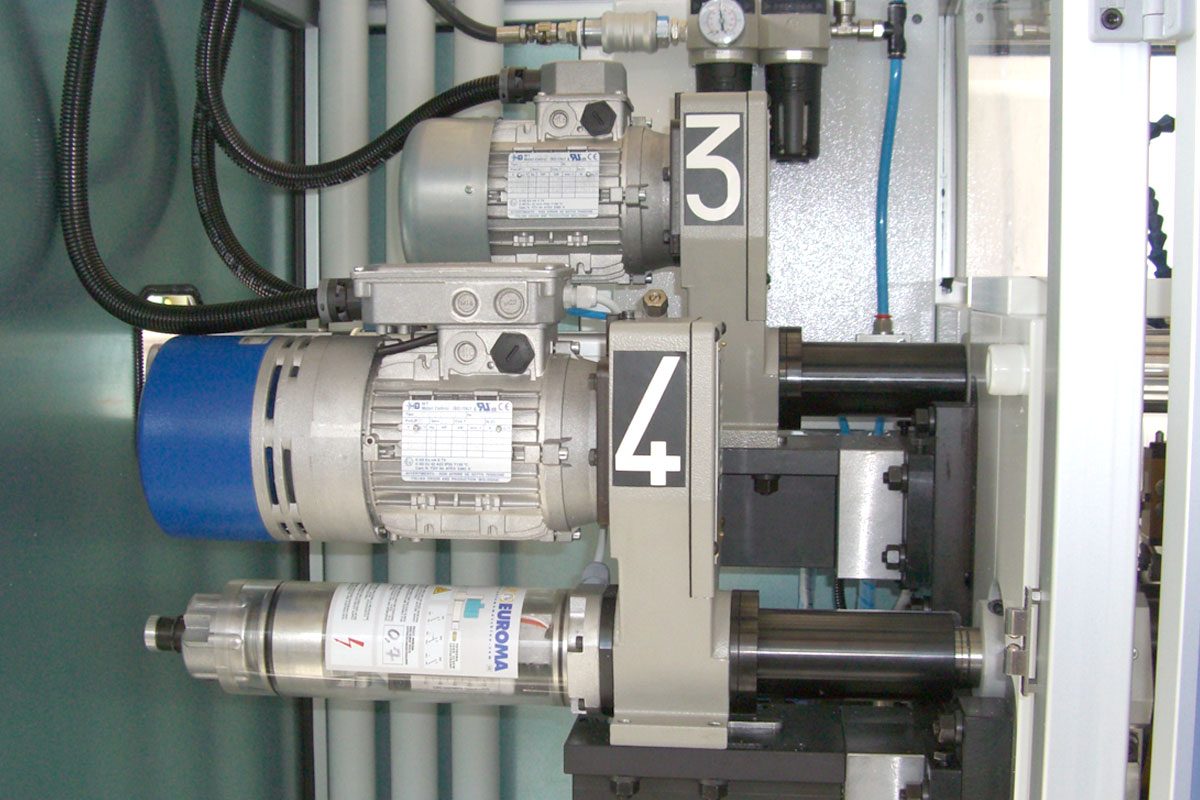

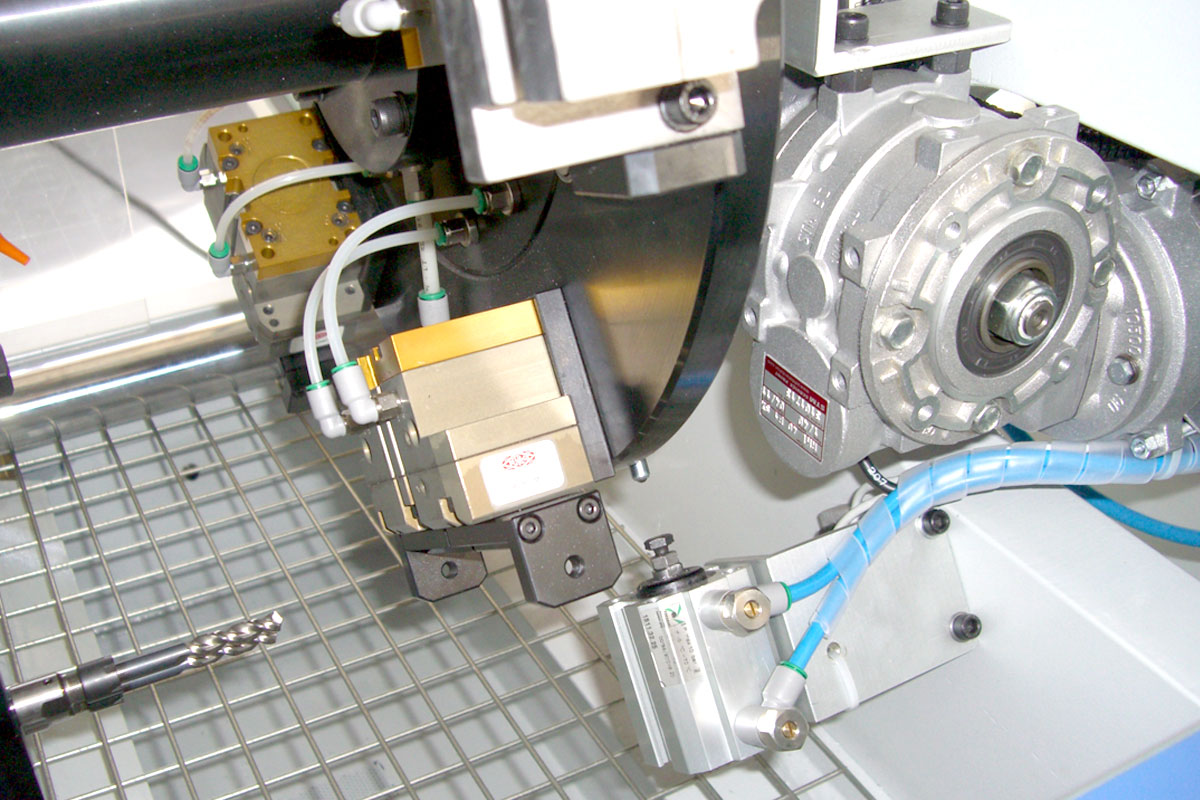

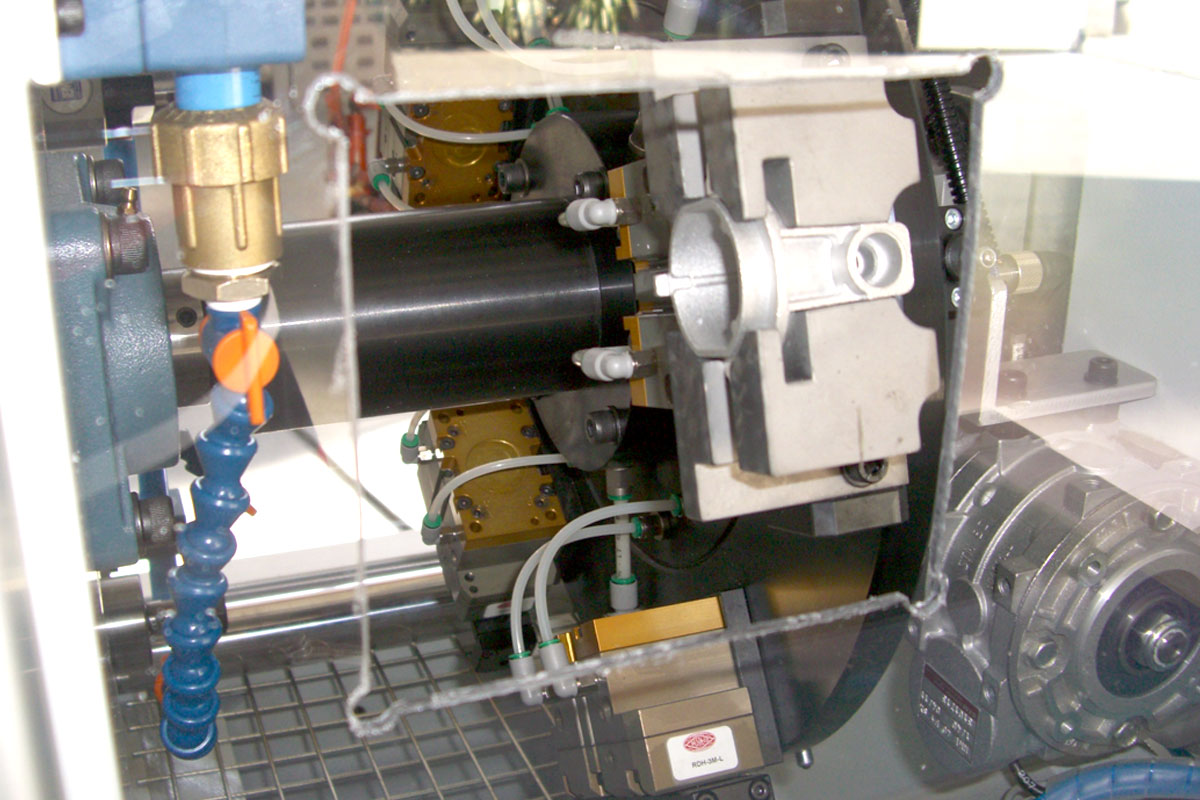

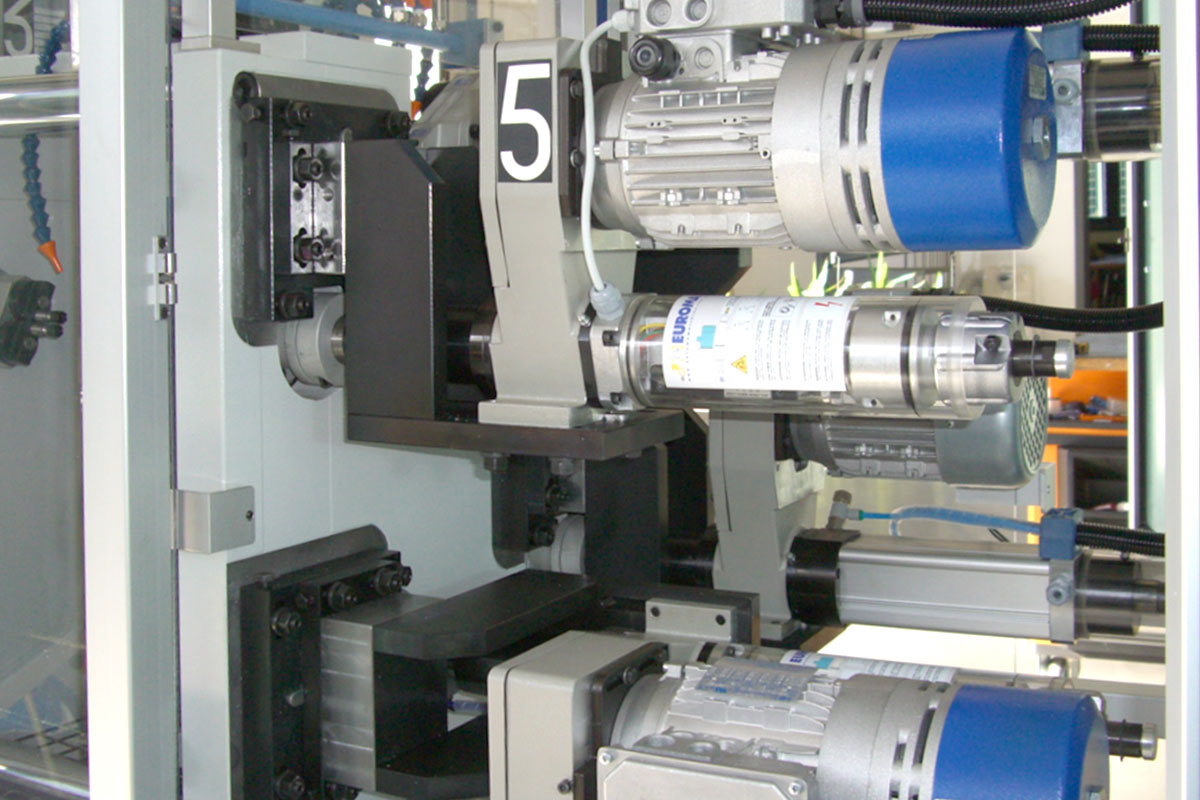

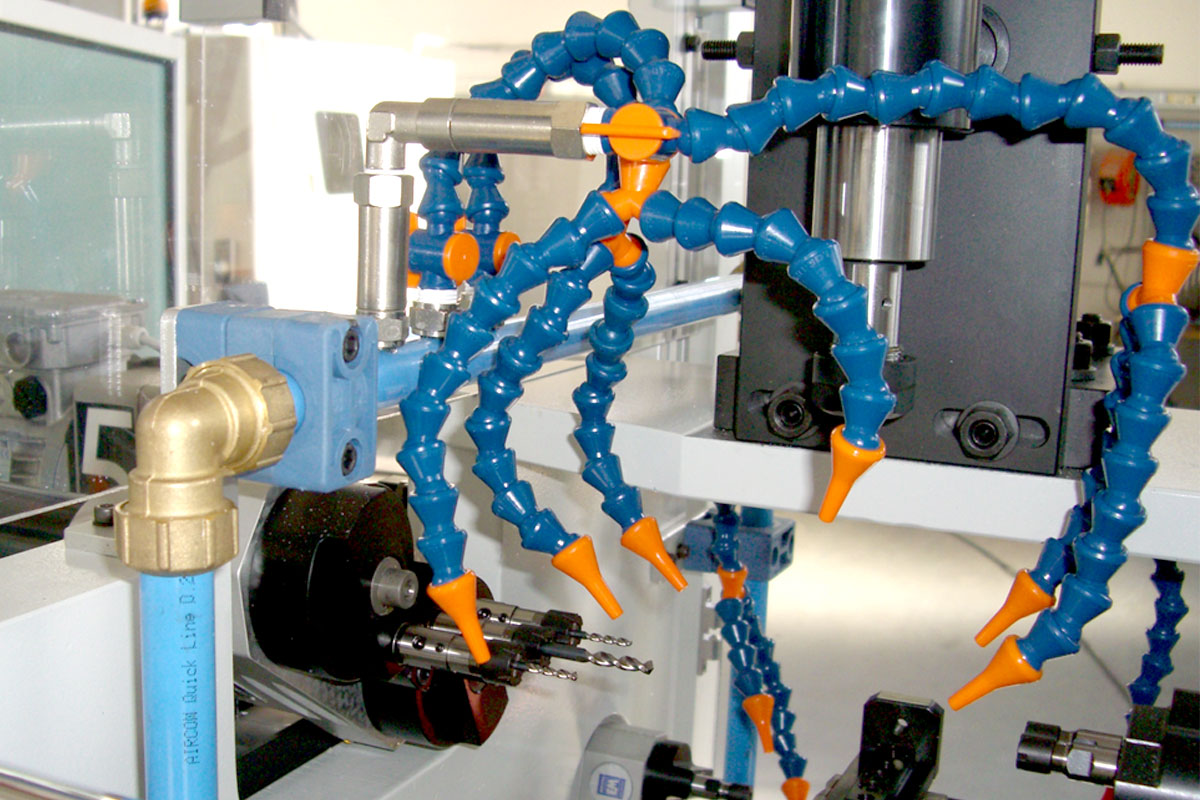

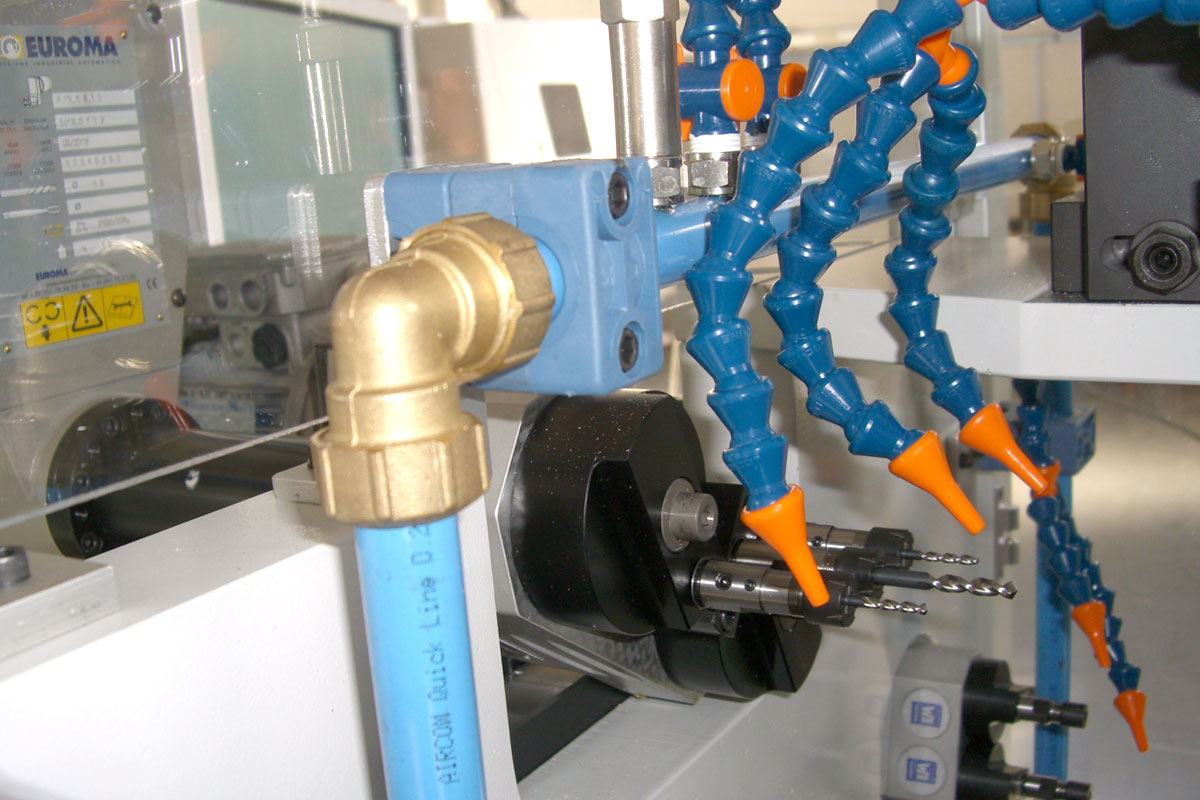

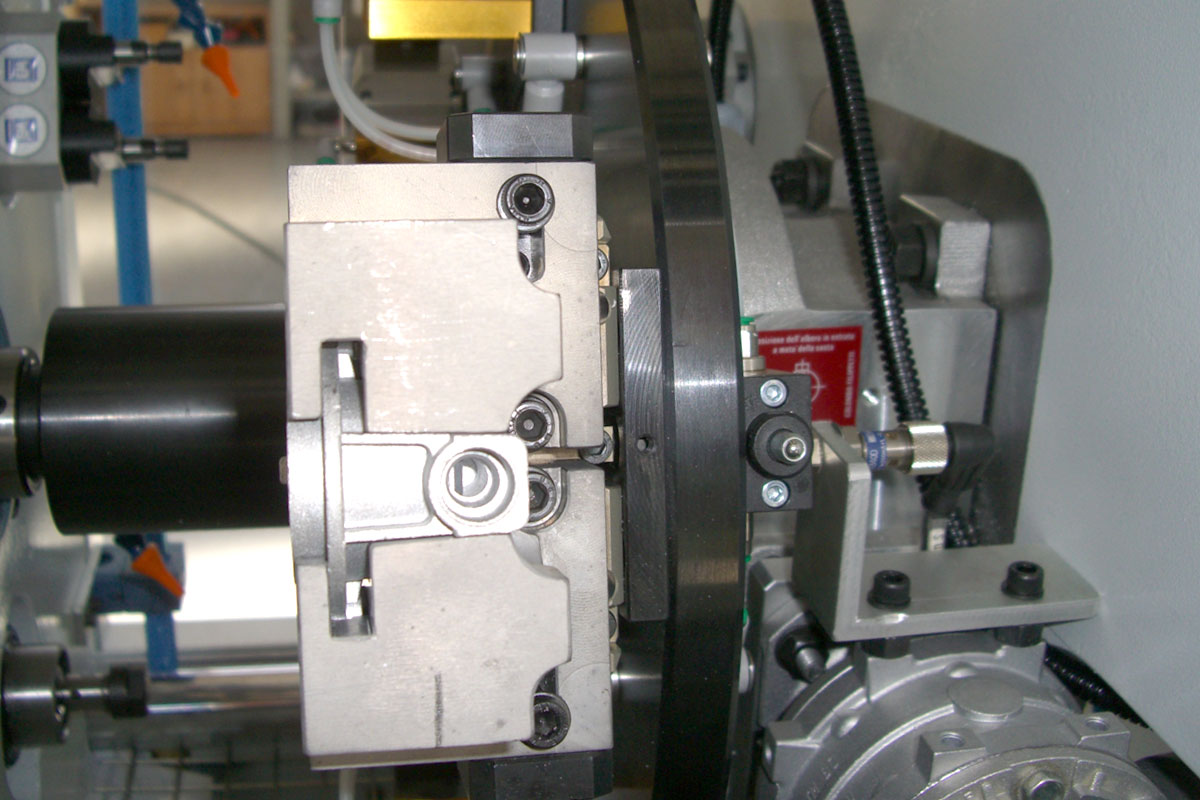

Tapping is numbered among the simplest, and most productive and advantegous aluminium threading methods. It enables operators to reduce machine downtimes, increase the speed of cutting operations and prolong the duration of the drill bit. Electro mac Srl has been specialized in the production of machines for foundries since its origins and has expanded its 60 years experience in order to offer the industrial market cutting edge systems for carrying out any aluminium threading work in a precise and safe way. The EM05/T7P5 machine is an example of this constant research and innovation. It is a real jewel as far as tapping is concerned. It is equipped with 6 work units. The system rests on an electro-welded steel platform. It consists of a rotating vertical base mod. RIG 06-04-270 VLRA-VCT with a 0,37 kW electrical motor with 4 positions and it is equipped with an aluminium disc with a diameter of 400 mm and a compressed air dispenser for blocking parts. This function is supported also by the 6 pneumatic clamps mod. D25 with parallel opening. The system is equipped with an automatic lubrication unit with a pump and a tank with a capacity of up to 5 litres, an electrical control panel with a NARDI PLC, a backlit numeric display, pushbuttons and warning lights for better visual control of the signals, 12 terminals and an aluminium perimeter protection system. Each work unit of the EM05/T7P5 aluminium threading machine has its own characteristics. The first machine drills a 5.2 diameter hole with a EUROMA system mod. F.P13.75.1600 carrying out 0.55 kW electro-mechanical drilling, it has a 75 mm stroke and is equipped with various accessories. The second unit carries out M13x1 tapping operations for housing nozzles and uses a EUROMA system mod. M13.50.A. It carries out 0.75 kW electro-mechanical tapping and has a 50 mm fast stroke. Unit 3 carries out two M4 tappings and consists of a EUROMA M.13.50.3200 model and of a head with two spindles with a distance between axles which can be adjusted from 18 to 130 mm. Unit 4 makes it possible to have a distance between axles from 13.5 to 69.5. The fifth unit makes it possible to carry out M6x0.75 tappings. The sixth unit is used to drill 6.5 diameter holes and the seventh and eighth to drill 3.3 holes.

APPLICATIONS

- Ø 5.2 drilling

- M13X1 tapping

- M4 tapping

- M6X0.75 tapping

- Ø6.5 drilling

- Ø3.3 drilling

ADVANTAGE

- Reduction of machine downtimes

- Increased cutting speed

- Longer duration of the drill bit

- Higher productivity

- Simpler to use

- Better economic advantages

- Average hourly production: 700/800 elements