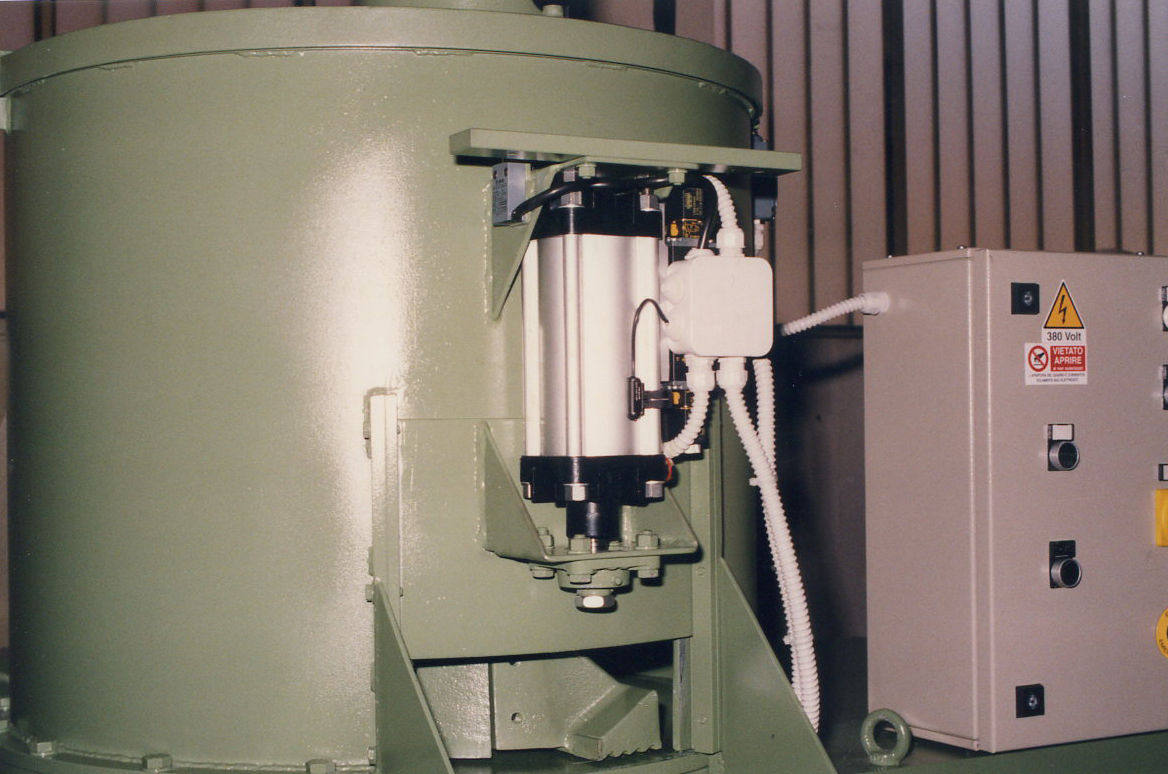

Mixer for mixtures based on silica sand

SLIDING HELIX MISCER DESCRIPTION

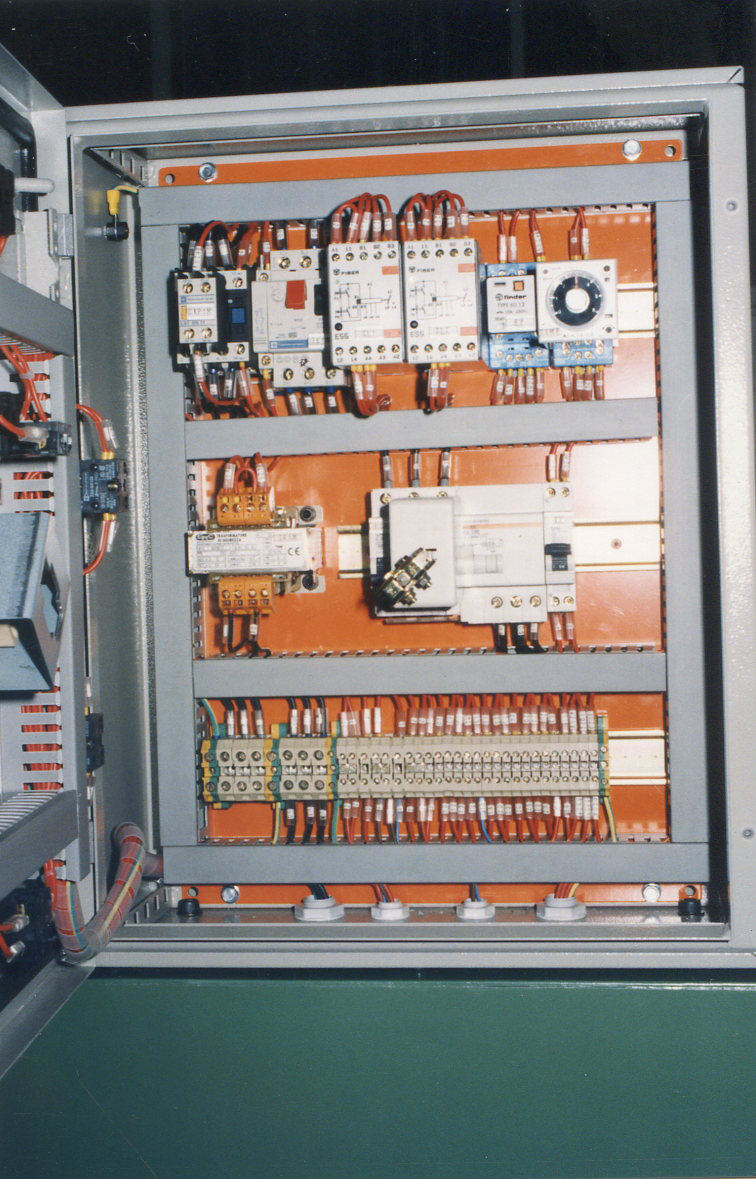

The competence and experience gained in almost 60 years has made Electro mac Srl aware of the importance of high performance machines for foundries. The production of top quality sand cores is a very important factor for improving the production process in terms of precision and of economic advantages. This is why Electro mac Srl focuses on the development of dosage dispensing units and mixing units for foundries and core makers characterized by easy use and maintenance, great functionality and best results. A perfect volumetric dosage dispensing system with adjustable calibration is indispensable for preparing silica sand mixtures to which liquid resin and catalysts are often added. These systems make the feeding of the mixing units used for constructing cores applying the HOT-BOX processes possible. Electro Mac Srl offers two different models of sliding helix mixers in order to meet the requirements of its customers in the sector of foundries and core making: the E50 and the E100 version. Both have a metal plate supporting structure and a frame of electro-welded tubular steel painted in RAL 6011 green. The model E50 and E100 sliding helix mixers are equipped with an electro-pneumatic control panel with bimanual push buttons and contemporaneous impulse for starting the machine and closing the mixture discharge door as well as with operation control warning lights.

MIXER UNITS mod. E50

- steel mixing tank with a thickness of 6 mm and a diameter of 400 mm

- Opening of the mixture discharge door driven by a pneumatic cylinder with a diameter of 80 mm and a stroke of 125 mm.

- Orthogonal axis reducer with gears in an oil bath with a reduction ratio of 1÷40 (30 rounds per minute)

- Three-phase electrical motor with a power of 5 Hp, 4 poles

- Sliding helix made of cast iron, complete with interchangeable scrapers

- Interchangeable tank bottom with a thickness of 10 mm

- Maximum mixture capacity: 50 kg in 180 seconds

MIXING UNITS mod. E100

- Steel mixing tank with a thickness of 6 mm and a diameter of 600 mm

- Opening of the mixture discharge door driven by a pneumatic cylinder with a diameter of 80 mm and a stroke of 125 mm..

- Orthogonal axis reducer with gears in an oil bath with a reduction ratio of 1÷40 (30 rounds per minute)

- Three-phase electrical motor with a power of 7.5 Hp, 4 poles (the voltage and the frequency must be specified at the time of the order)

- Sliding helix made of cast iron, complete with interchangeable scrapers

- Interchangeable tank bottom with a thickness of 10 mm

- Maximum mixture capacity: 100 kg in 180 seconds