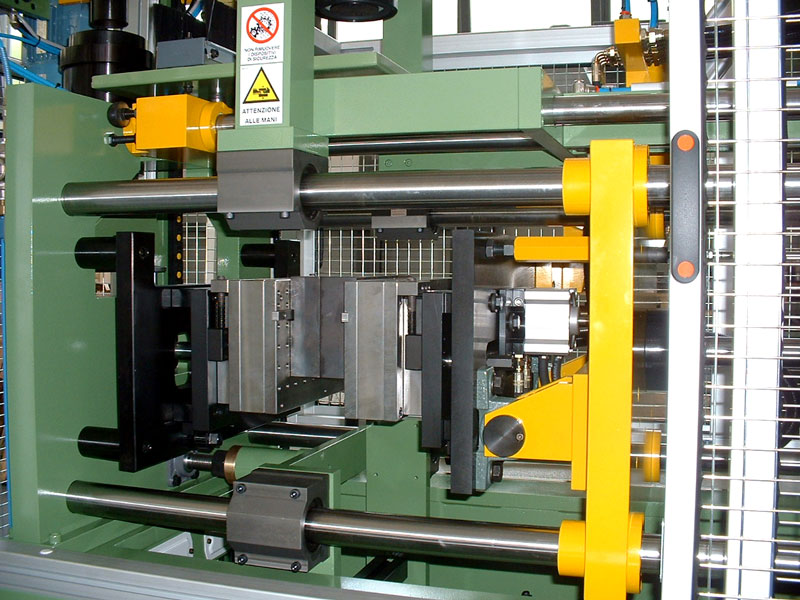

DESCRIPTION OF THE ELMAC F1 machine

The ELMAC F1 machine for foundries is a universal product for forming sand cores using the Hot Box system. Electro Mac Srl offers the market this top quality, very reliable and extremely precise machine: cores have no burr and they are compact, even if sand is injected at a low pressure. This exceptional qualitative result is made possible by a mould tight closure system supported by four hardened, ground guiding columns and by a mould holder car moved by means of a hydraulic cylinder able to develop a closure force of 3,000 kg. The mould heating plates are made of highly non-deformable special steel in order to guarantee perfect and tight closure of the mould at any operating temperature. This is indispensable to obtain homogenous and well pressed surfaces of the sand cores. The Elmac F1 machine of Electro Mac Srl is particularly easy to use and to maintain even by non-specialized staff. This results in a significant reduction of rejects, control times and machine downtimes and in an increase of the production yield and savings. The structure of the bed of the Elmac F1 automatic machine is made of electro-welded steel with a thickness of 10 mm. Sand cores are transported to the mould by a conveyor belt. The central extraction of the workpiece is carried out by the mobile tilting part of the plate. The hydraulic control unit is equipped with electrovalves and a filter located on the discharge. The pneumatic panel is mounted on board the machine and it consists of electrovalves with an ISO base. Furthermore the Elmac F1 machine is equipped with an auxiliary keyboard complete with selector switches for manual handling and for setting the work cycle. The work cycle times can be saved from 0 to 9.