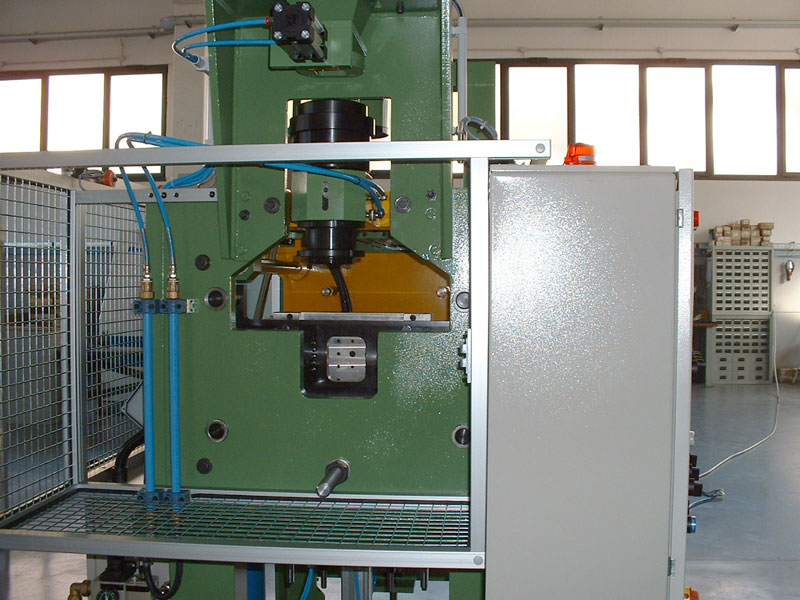

Automatic machine for forming sand cores with the HOT-BOX system

DESCRIPTION OF THE ELMAC ECO 3.0 MACHINE

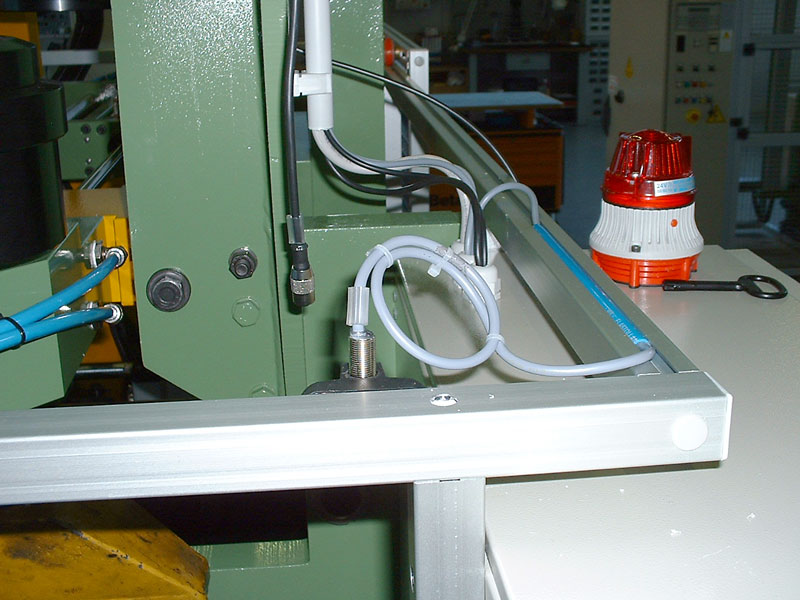

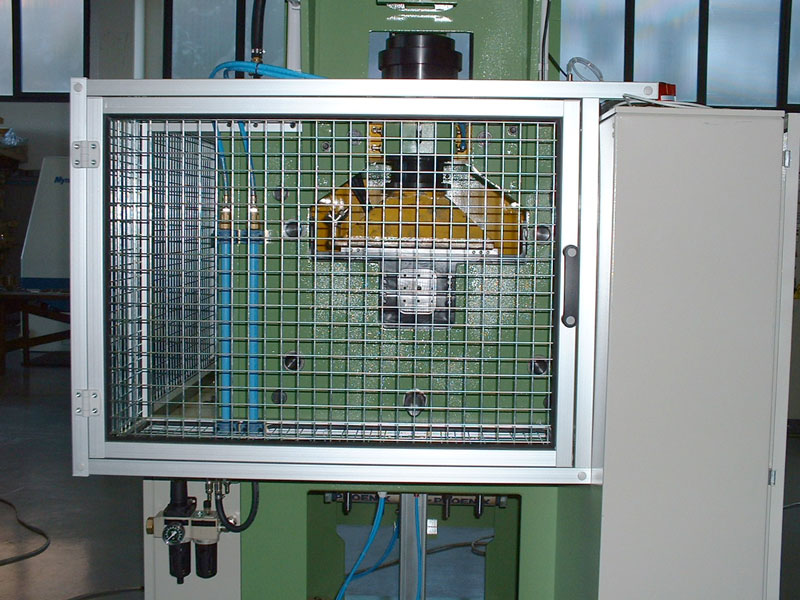

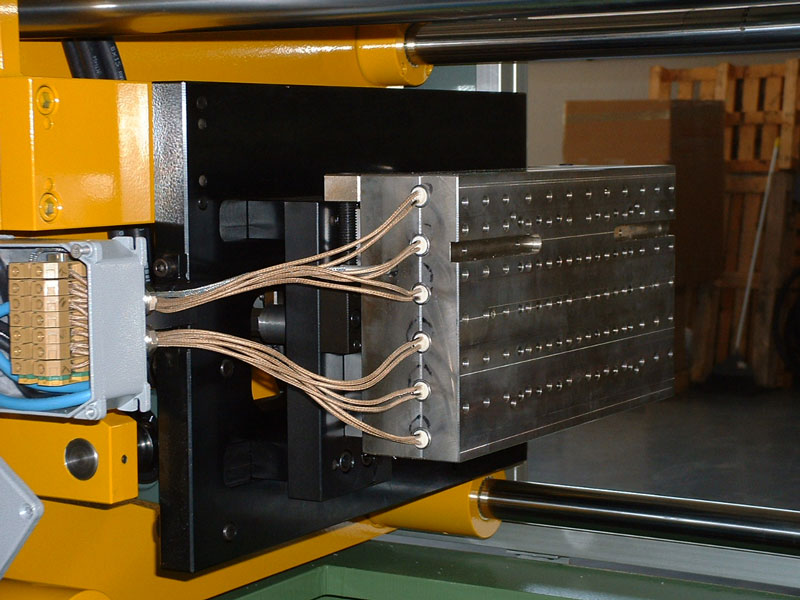

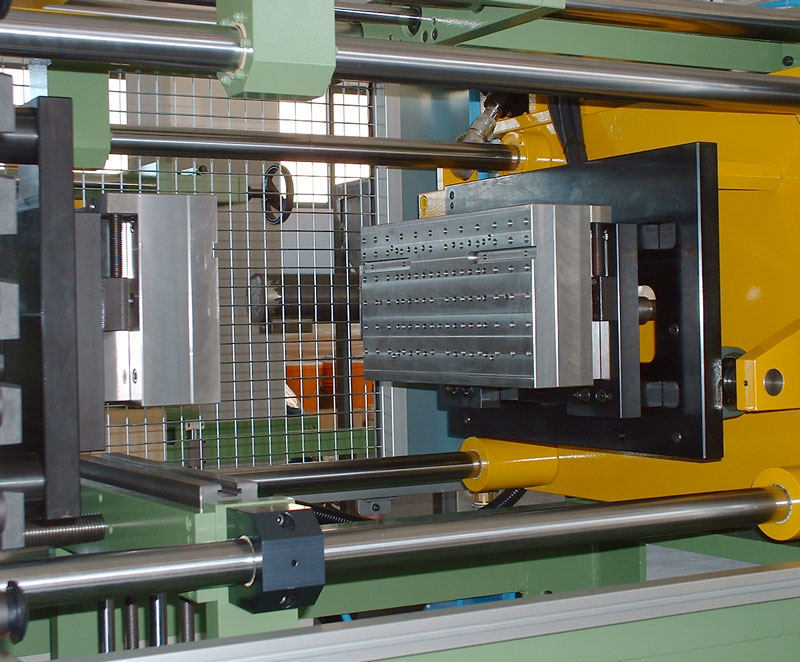

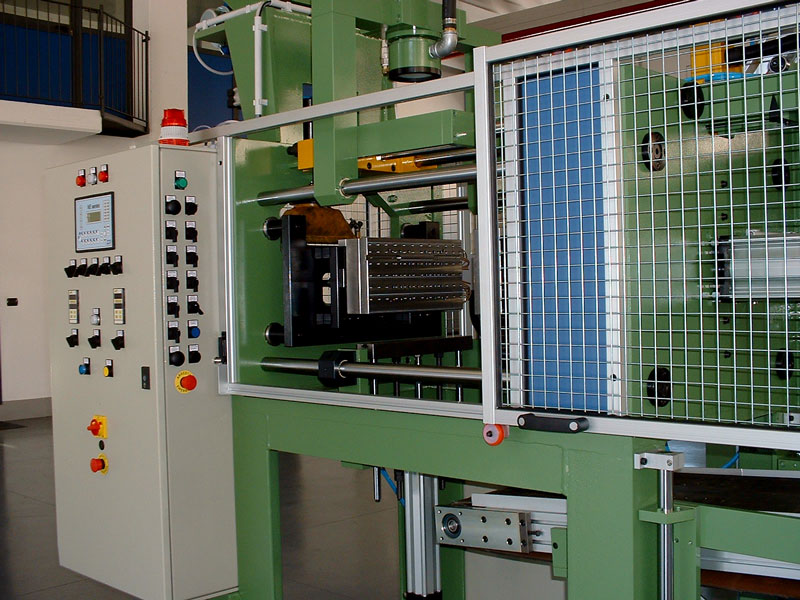

ELMAC ECO 3.0 is one of the latest technological findings for sand core forming with the HOT BOX system. Electro Mac Srl, who has been a leader in the production of automatic machines for foundries and core producers for more than half a century offers the market the fruit of its efforts and investments in the research and development of innovative solutions which improve the quality of work and industrial productivity and offer a significant economic advantage. The ELMAC ECO 3.0 equipment makes it possible to obtain excellent technical results and optimal visual characteristics: solid and uniform sand cores without residues. This is possible even when low pressure injection is used. They are no longer a mirage, but an actual industrial solution offered by Electro Mac, permanently committed to offering advanced machinery. The bed of this sand core forming machine is made of electro-welded steel with a thickness of 10 mm. The opening and closing cars move on hardened and ground steel columns with a diameter of 40 mm, while the mould is started and stopped by a pneumatic system. The conveyor belt of the sand cores approaches the mould. The central extraction of the workpiece is carried out by the plate tilting mobile part. The position and stroke of the radial, vertical extraction can be adjusted during the pulling phase. The system is equipped with an electrical supply (12V/1500 W) for the cartridge resistance units used for heating the metal pin. The mould heating plates are made of highly non-deformable special steel which guarantee perfect and tight closure of the mould at any operating temperature. The pneumatic and electronic control panels are installed on board the machine. An auxiliary keyboard with selectors for moving the machine manually and setting the work cycle is also available. A further very important characteristic of the ELMAC ECO 3.0 core forming machine is a fixed hopper, equipped with a motor vibrator and a protection system. The protection system consists of extruded aluminium profiles and of a zinc plated metal net. It is equipped with sliding doors which enable operators to access the various parts of the sand core forming system safely and easily.

APPLICATIONS

- Foundry products

- Alloy castings and microcastings

- Sand and shell castings

- Pressing and forming

ADVANTAGES

- – better product quality

- better resistance to wear

- fewer rejects

- higher productivity

- immediate operability

- extremely simple use