Automatic machine with controlled axes for cutting runners for foundry products

DESCRIPTION of the CnCut/R200 machine

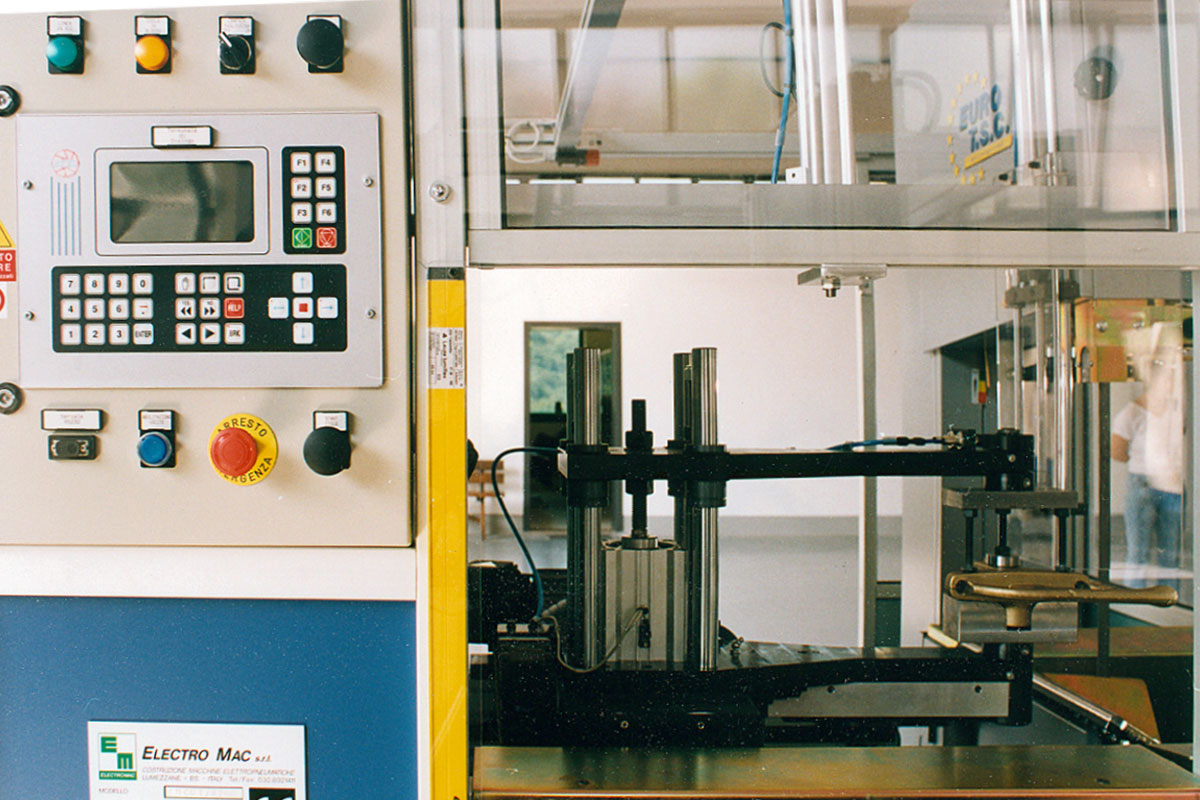

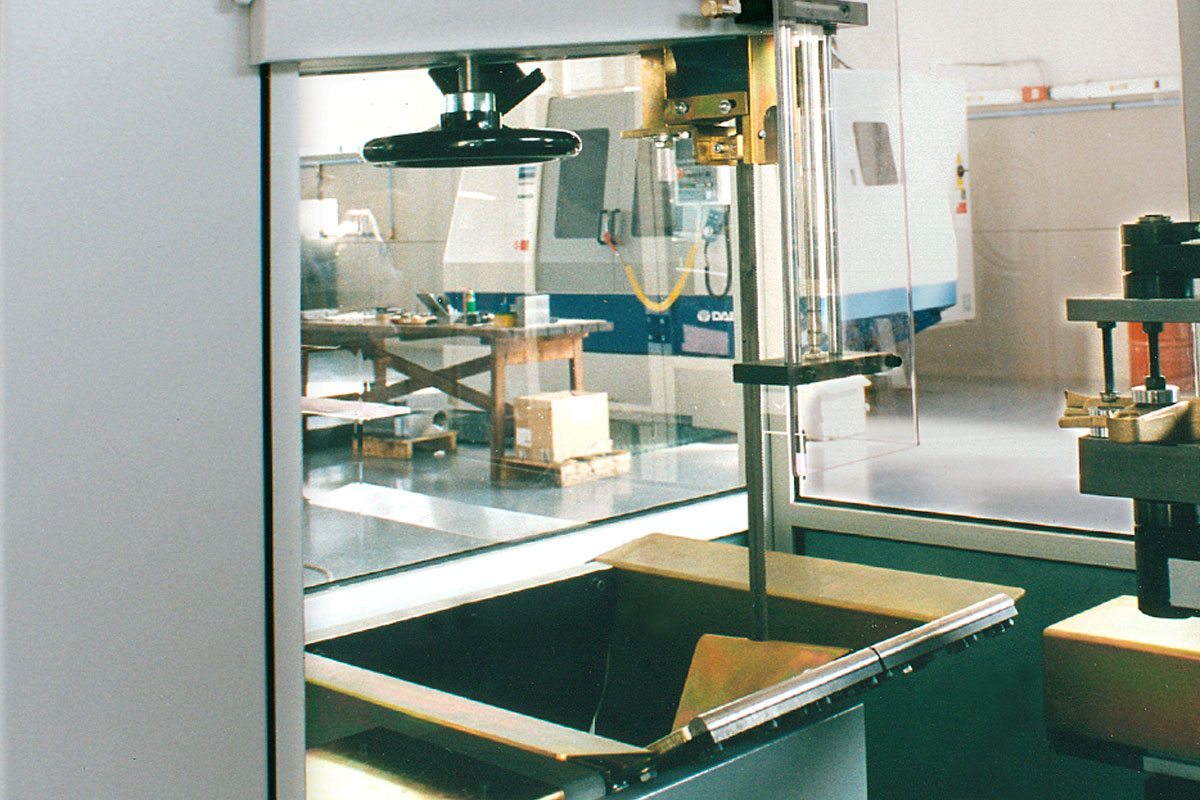

The CnCut/R200 machine is the latest novelty manufactured and offered by Electro Mac Srl. It represents an innovation in terms of safety for cutting runners in the field of cast metal products. This machine makes it possible to carry out shaped cuts, radiuses and arches fully automatically. It is equipped with Cartesian axes managed by a numerical control system, which is very easy to programme and has a wide storage capacity: it is possible to store 200 work programmes and to interpolate all movements of the axes with very great precision, making processing particularly accurate and keeping it unvaried in time. The reduction of the tooling times of the CnCut/R200 is a great advantage, because it eliminates production downtimes almost completely and optimizes the management of cutting processes. Blades last longer and guarantee perfect cutting operations which are safer and easier for the personnel and require less effort: this leads to a significant increase in the Company’s productivity. The machine support structure for cutting runners is made of heavy 90 x 90 aluminium profile. It is equipped with height adjustable feet allowing for anchorage to the floor. The band saw model M 520 is driven by a 380V/50Hz three-phase asynchronous motor. It is equipped with a metal chute for discharging burr and materials to the outside of the machine, a blade with special toothing, specifically developed to cut non-ferrous metal, a scrap collection tray located in the lower part of the sawing machine and a 150W low voltage halogen lamp for illuminating the work field. The rotation speed is 400 rounds/min.

APPLICATIONS

- Foundries producing aluminium cast rims

- Light alloy castings for the automobile industry

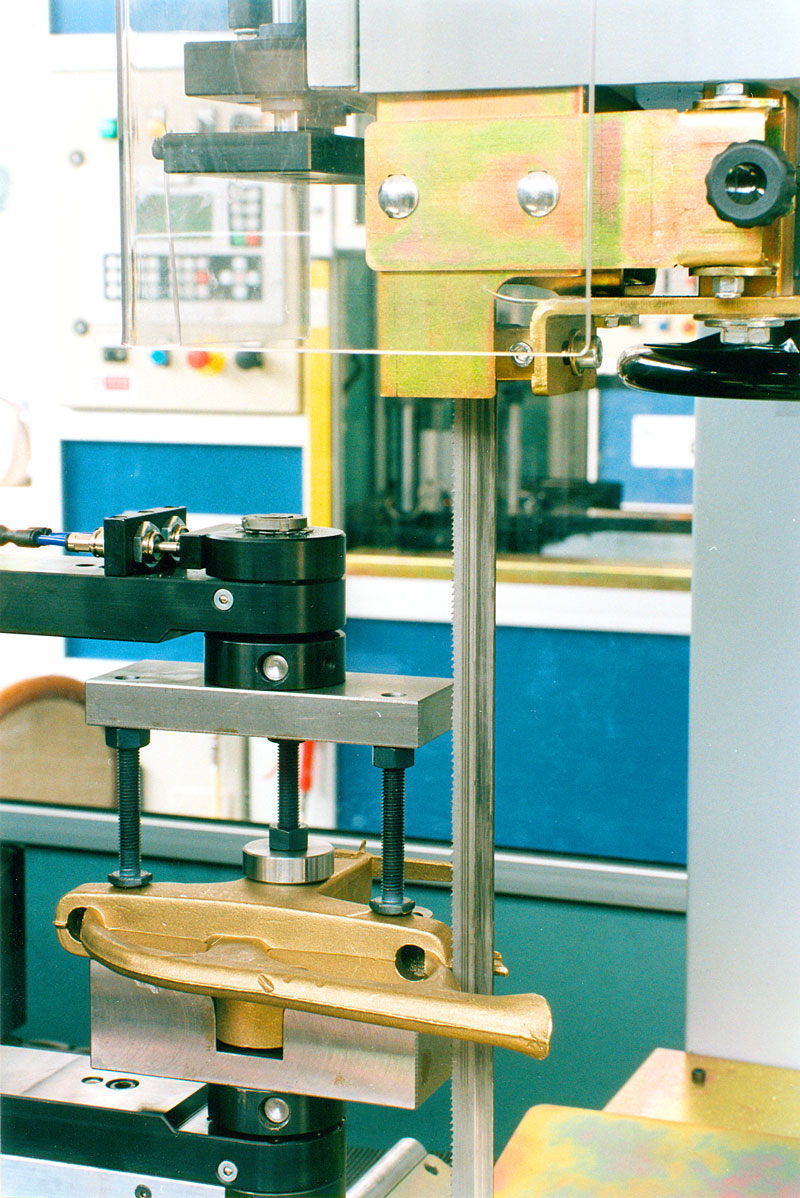

- Brass castings for taps

- Brass castings for valves

- Aluminium castings

- Bronze castings

- Cast iron castings

- Alloyed steel microcasting

ADVANTAGES

- Extreme operator safety

- High productivity

- Reduction of dead times

- Quick tooling

- Simple programming

- Large storage capacity

- Longer duration of the cutting blade

- Cutting precision

| Overall dimensions | |

|---|---|

| Front width | 1.900 mm. |

| Depth | 1.500 mm. |

| Machine height from the floor | 1.850 mm. |

| Weight | 650 Kg. |

| Axes | |

|---|---|

| X axis max. stroke | 600 mm. |

| Y axis max. stroke | 500 mm. |

| Z axis max. rotation | 360 Gradi |

| Operating voltage | |

|---|---|

| Supply voltage | 220/380 V. |

| Auxiliary voltage | 24 VDC |

| Frequency | 50 Hz |

| Characteristics | |

|---|---|

| Sawing machine electric motor | 3.0 Hp |

| Max. blade extension | 4.300 mm. |

| Electric motor rotation speed | 1.400 GPM |

| Flywheel speed (for brass) | 400 GPM |

| (Other speeds on request) | |

| Vice | |

|---|---|

| Vice stroke | 80 mm. |

| Cylinder diameter | 80 mm. |

| Vice closing force at 6 Atm. | 300 Kg. |

| Max. piece rotation diameter | 500 mm. |

| Optional |

|---|

| Blade rotation speed variator |

DESCRIPTION OF THE INTERPOLED AXES

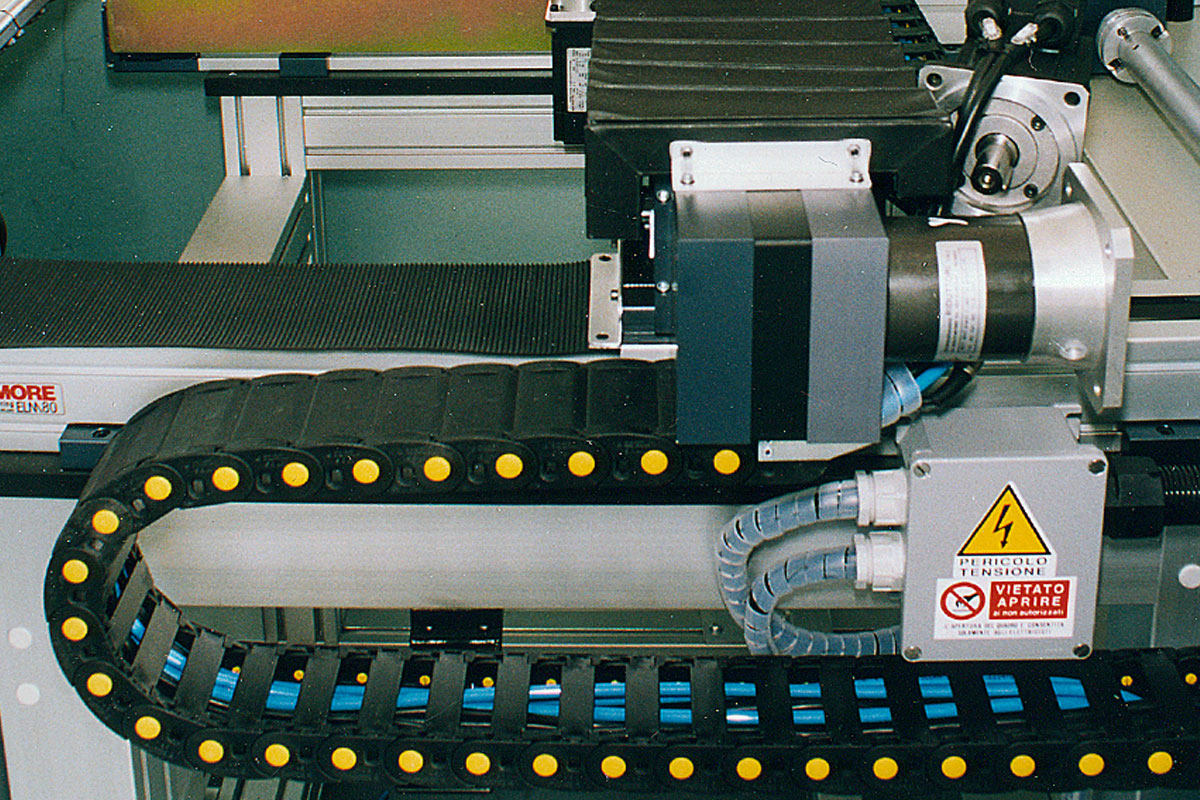

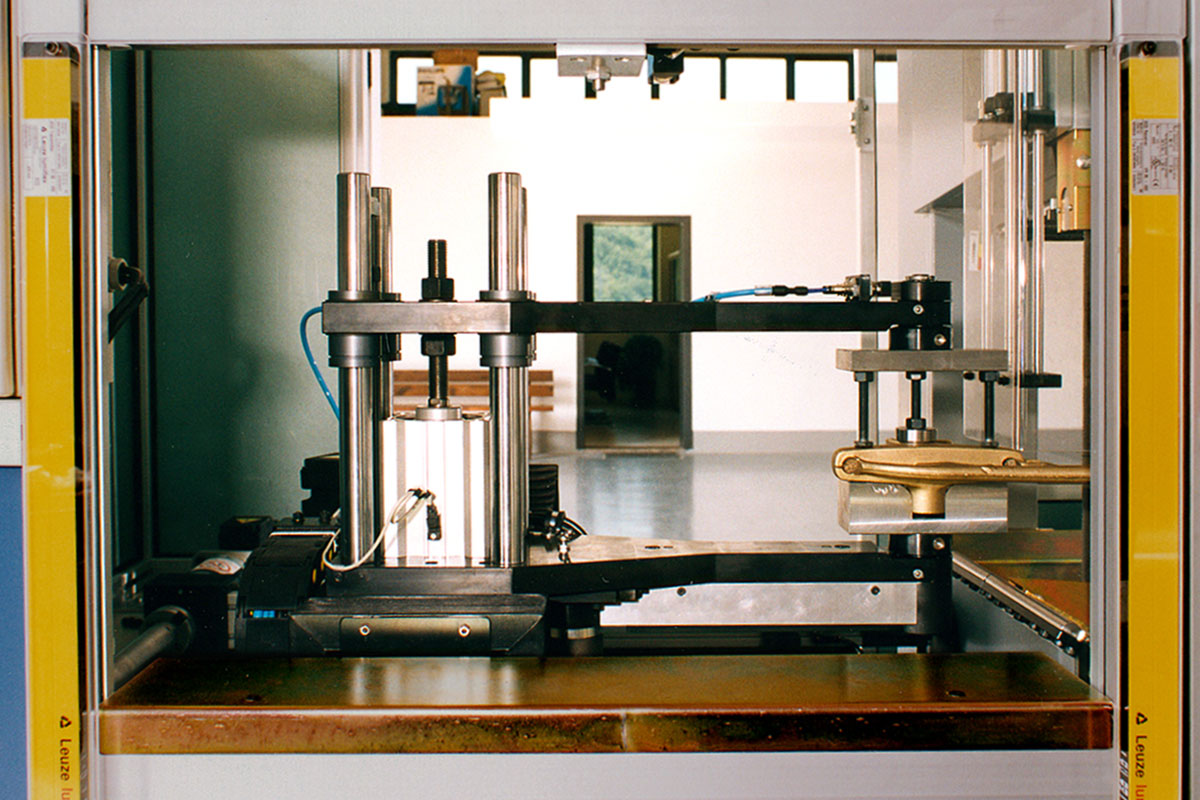

The X-axis of the CnCut/R200 machine consists of 2 linear units, mod. ELM 80 RSH, with a useful stroke of 470 mm., parallelism shaft with disc couplings, proximity switch for controlling the maximum axis stroke, epicycloidal step-down gears mod. BGT 1050/2/12/15 SK and a Brushless Parker motor, mod. SMB 82, torque 3 nm, 3000 rounds. The Y-axis consists of 1 linear unit, mod. ROBOT 130 NTS, with a useful stroke of 500 mm., a proximity switch for controlling the maximum stroke of the axis, epicycloidal step-down gears mod. BGT 800/2/12/15 SK and a Brushless Parker motor, mod. SMB 82, torque 3 nm, 3000 rounds. The Z-axis consists of 1 pneumatic vertical clamp guided by 4 hardened columns for picking the workpiece to be cut. The maximum opening stroke is 80 mm. There are a chain drive for rotating the piece and epicycloidal step-down gears mod. BGT 600/2/30/15 SK and a Brushless Parker motot mod. SMB 60 with a torque of 1.4 nm 3000 rounds

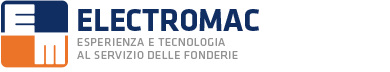

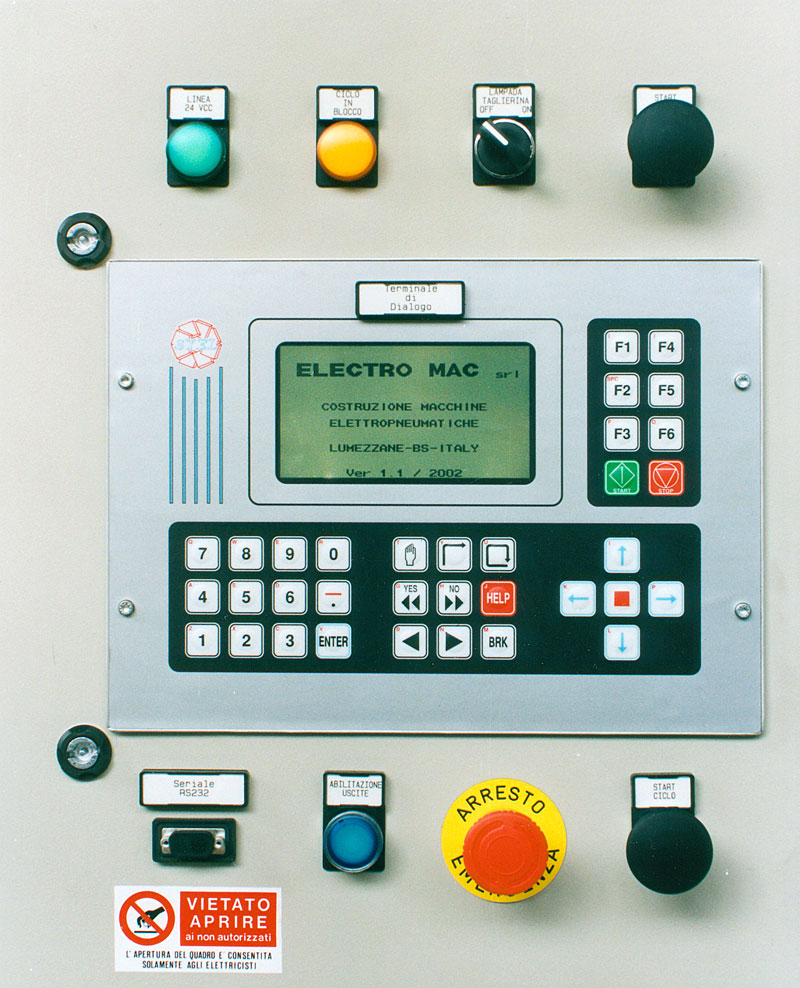

ELECTROTECHNIQUES

The CnCut/R200 electrical panel mounted on board the machine includes the electronic control equipment (operation boards) of the motor driven X, Y and Z axes. It is managed by means of a SYEL numerical control system mod. CN84, with a backlit 4×40 display, selector switches for manual movement and function control warning lights.

The external connection of the CNC takes place through an RS232 SERIAL LINE which makes the connection to a PC possible, in order to save the work cycles. The remote keyboard for moving axes manually is used to acquire the tool path data POINT BY POINT with reference to the workpiece to be processed. The pneumatic panel is equipped with electrovalves and pressure regulators and mounted on board the machine.

SELF-LEARNING SYSTEM

IThe data and displacement acquisition system is based on the SELF LEARNING METHOD. The remote keyboard makes it possible to move the axes to the desired point, save the position, move to another point, save again and so on, until the cutting cycle is completed. When the cycle is launched and automatically acquired, the axes go over to the point previously saved in the SELF LEARNING phase. This work cycle can be saved and recalled later from the USER MEMORY of the machine, after assigning a recognition number to it. This user memory has a great storage capacity: up to about 200 work cycles.

SAFETY SYSTEMS

The CnCut/R200 machine is equipped with a pair of safety and control light curtains (receiver + transmitter) certified and manufactured in accordance with the PR. EN 50100 1/20 and 89/392 EEC European Standards. Total height 450 mm, power supply 24 V cc, 2 output channels (1.2A-40 V cc), intrinsic safety, self-test, TX-RX work distance: 0–6 m. (Otp. 16 m.).The machine is supplied with a perimetral safety enclosure made up of an aluminium profile frame and transparent polycarbonate panels. The machine is provided with access doors controlled by safety end-switches which make maintenance and cleaning easier.